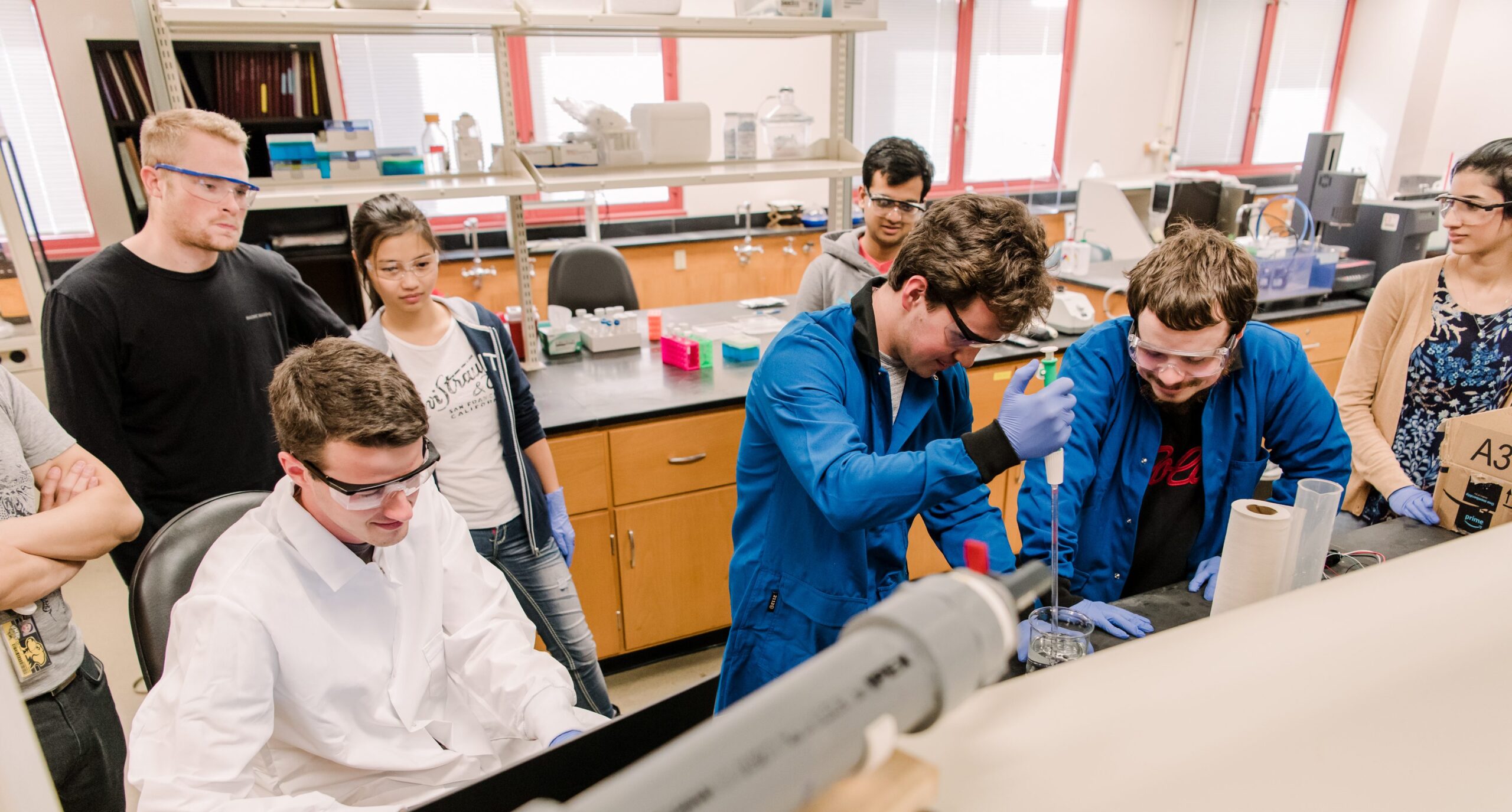

In a chemical engineering lab, students huddle around a bench layering aluminum foil and steel wool together to build a battery. Another group pipettes solutions into a pressure vessel to test various reactions. The end result of the students’ experimentations will be two autonomous shoebox-sized vehicles that are powered by chemical reactions. Think of your second-grade volcano project, but the baking soda and vinegar “eruption” is happening inside an enclosed vessel, propelling it forward down a track.

When the UMBC Chem-E-Car chapter launched in early spring 2019, there were 10 students who came together to grow the group. Today, less than one year after they became formally recognized by UMBC and the American Institute of Chemical Engineers, there are about 30 students working together to build vehicles powered by chemical reactions, putting the information and skills they learn in their classes into practice.

Students work in three groups on two vehicle projects. One team focuses on developing the stopping mechanism that uses a color changing reaction, the second team works on refining the car propelled by a pressure-generating reaction, and the third team develops a battery-driven vehicle.

“One car moves using a chemical reaction that produces a large volume of gas, and the gas is used to move a pneumatic motor, which is kind of like a water wheel for air,” explains Sammie Maygers ’20, chemical engineering, who is leading the group in charge of developing the stopping mechanism. “The second car is powered by a battery. We are experimenting with different chemical reactions to optimize the amount of current and voltage that we can produce to run an electric motor.”

As the group was ramping up, the founding students spent the semester learning about the structure of the competitions and attended the regional competition as onlookers. Alex Von Gunten ’20, chemical engineering, current chair of the Chem-E-Car Project, says that it was helpful for UMBC students to experience the competitions and to take note of the vehicles that other teams built. An additional layer of pressure for competitors is that no one knows how far their car will need travel until a couple of hours before the race, when the judges release the specifications that the car must meet. Just before the car is set to race, the students work through a series of calculations to determine the amount of chemicals that are needed to propel the vehicle a specific distance.

Jason Ewart ’20, chemical engineering, who is a member of the pressure team, explains that safety is a very important component of the Chem-E-Car competitions. The students who are taking part rely on the knowledge they’ve learned in the courses they have taken at UMBC, including the safety course that all chemical, biochemical, and environmental engineering students must complete.

The Chem-E-Car group joins a rich history of student organizations on campus that design and build vehicles based on skills learned in the classroom. On a human scale, UMBC’s Baja SAE team builds vehicles that are driven by one student and are designed to withstand challenging terrain and weather while keeping budget, vehicle weight, and agility in mind. In the 2018–2019 season, the Baja team finished with the second highest total points in the program’s 30-year history.

The Chem-E-Car team has yet to test the mettle of their designs, but they plan on competing in the regional competition at Virginia Tech in April 2020, with their sights set on advancing to the national competition.

***

All photos, including header, by Marlayna Demond ’11.