Seniors in Neil Rothman’s capstone mechanical engineering class experience the ups and downs of designing for real-life clients.

By Megan Hanks

In the real world, the more projects and problems an engineer works on, the better they get at coming up with solutions that actually work. That’s why, during the final year of UMBC’s mechanical engineering curriculum, students spend a semester working through the “hard knock design experiences” they need to succeed as engineers.

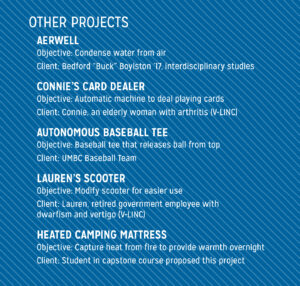

The projects are presented to the class at the beginning of each semester by Neil Rothman, professor of practice of mechanical engineering, and come from a variety of places, including private companies, local nonprofit organizations, and some UMBC-affiliated teams and groups. Throughout the semester, students work in groups of three or four to design, create, test and deliver nearly a dozen high quality products – everything from a calming swing for a boy with disabilities, to a GPS-guided robot, to a machine that automatically shuffles and deals a deck of cards.

Rothman hopes the course helps students recognize how little they know, and encourages them to seek guidance from experienced engineers. “The more times you design engineer something, the better you get,” he says.

Several projects, including a swing for a boy named Brennon’s happened through a collaboration with V-LINC, a Baltimore-based organization that creates customized technological solutions for people with disabilities. Brennon, a young boy who has Type 1 lissencephaly, which causes developmental delays, seizures, and abnormal muscle tone, is calmed by the swinging motion. Swinging also helps reduce the frequency of the seizures that he experiences.

Many students face challenges and setbacks throughout the semester, including some groups who simply run out of time to complete the project. Brennon’s swing, for instance, is still in progress as of press time, so the group continues to put the final touches on the swing so that it will meet the needs of their client. Rothman says that “the design engineer’s best friend is experience.”

Ciara Davis ’17, mechanical engineering, who worked on Brennon’s swing, knew that she wanted to work on a V-LINC project. “I liked that the project we would be doing would be going to someone to help them in some way,” she says.

For Danny Joh ’17, mechanical engineering, who worked with Davis, meeting Brennon was a pivotal moment. “Every single thing I did, I had to think about Brennon. A single thing I did wrong could affect his life,” he says.

For Danny Joh ’17, mechanical engineering, who worked with Davis, meeting Brennon was a pivotal moment. “Every single thing I did, I had to think about Brennon. A single thing I did wrong could affect his life,” he says.

Another group developed a GPS-guided robot for the Aberdeen Test Center. The project was proposed to Jay Gordon ’17, mechanical engineering, who interned at the Aberdeen Test Center, and combined mechanical engineering with software engineering skills. The goal of the project is for the robot to be able to follow a soldier in a field and maneuver itself around obstacles, and stop and start at specific points in the field. One requirement was that the robot needs be waterproof so that it can be used outside.

Emily Casto ’17, mechanical engineering, one of the group members, explains that the project allowed her to participate in experiences that helped her grow as an engineer. “I think from this project specifically, I think the biggest takeaway is that being pushed out of your comfort zone is really scary, but it really pushes you to learn and to understand something new,” she says. “This is what engineering is. It’s never the same thing over and over again.”

[nivoslider id=”8509″]

Use the arrow buttons to the right to scroll through the slide show.

Photos by Marlayna Demond ’11 and Dusten Wolff ’13

Tags: Fall 2017